Blackcurrant, bergamot and maple syrup

Medium body

The acidity is pronounced but very nicely integrated.

A coffee with berries but also nutty notes, maple syrup and a light floral note.

The mouthfeel is syrupy and smooth.

Kenya with a difference! That was our motto for the Muburi. It won us over with its berry notes and sweetness. But we specifically wanted a Kenyan that would also work as an espresso, so that it would suit everyone! It is a real stunner and full of a variety of flavors. Currants but also nutty notes and maple syrup can be found in this coffee, accompanied by floral and citrus notes!

Nevertheless, it can easily be enjoyed as a filter coffee, which is fun for everyone!

Try it out and be enchanted!

Medium coarse ground coffee: 15g

Water: 250ml

Temperature: 95 °C

First pour: Let the coffee swell with 50ml water for 35 seconds

Second pour: Carefully and gently fill up to 250ml

—

Total extraction time: 2min 45sec

Fine ground coffee: 18g

Extraction volume for 2 espressi: 50g

—

Extraction time: 26sec

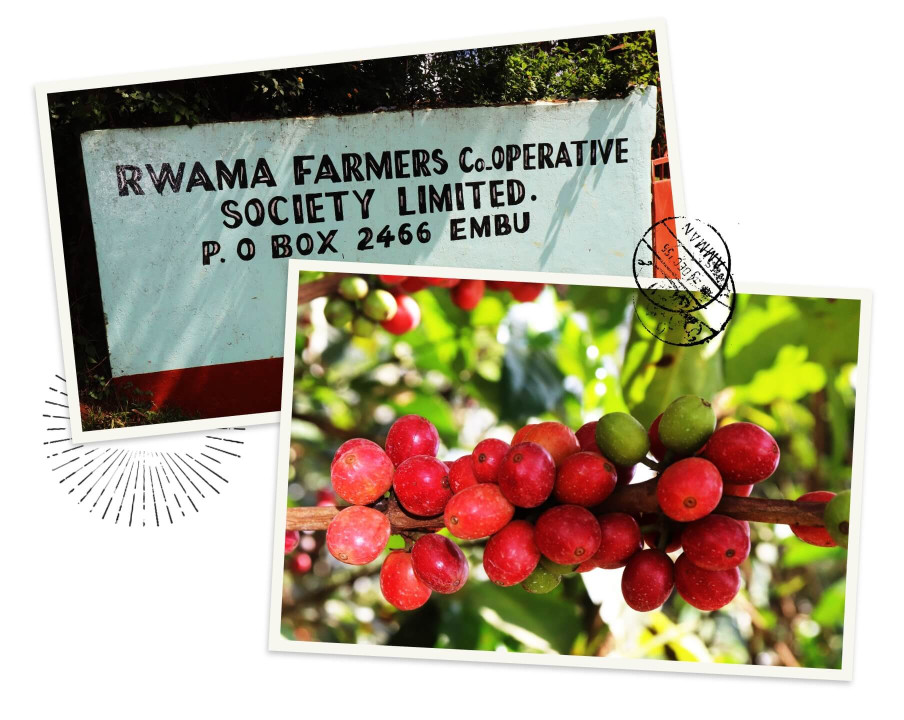

Belonging to the Rwama Coffee Farmers Society, Muburi Factory consisting of 1,200 active members. Founded in 1964, it occupies a 7-acre area catering to Gituga, Kiangoro, Muburi, and Kagukuma villages. Operating as a wet mill and cooperative headquarters, the facility is overseen by the factory manager and a team of 7 staff members, including permanent and temporary personnel. Their responsibilities include coffee weighing, selection, grading, farmer payments, and addressing farmer concerns.

Muburi factory is located in the village of Rwama, in the Gichugu division in Kirinyaga County. The nearest big town is Kianyaga (approximately 5 km away), which is also a couple of hours drive from the capital Nairobi.

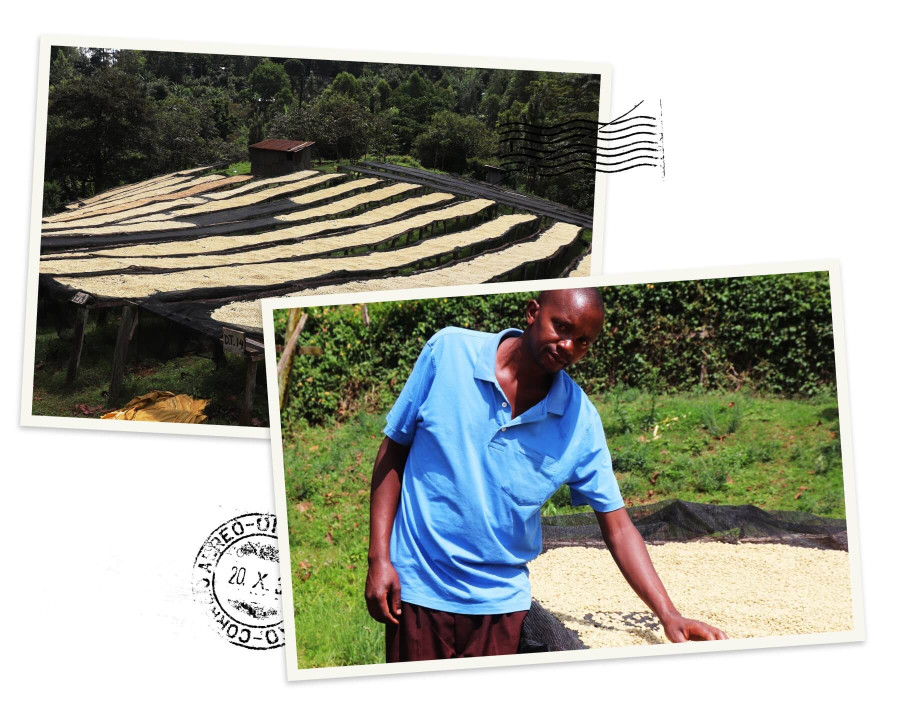

The factory has cherry collection points (catchment) and a washing station in the area where local farmer members of the cooperative deliver coffee cherries for regional bulking. The cherries are hand sorted, washed, fermented, and laid out on raised beds to dry. They are then hand sorted for defects again. 99% of coffee grown is of the SL-28 variety, and 1% Ruiru 11.

Demonstration plots are planted at the factory to reinforce the best practices taught throughout the year. After picking, ripe cherry is brought to the factory before it undergoes processing to remove the skin and pulp – known as the wet processing method. Wastewater is discarded in soaking pits, and is also recirculated for conservation.

The factory uses a disc pulper with three sets of discs to remove the skin and fruit from the inner parchment layer that is protecting the green coffee bean. After pulping, the coffee is fermented overnight to break down the sugars, before it is cleaned, soaked and spread out on the raised drying tables. Time on the drying tables depends on climate, ambient temperature and volumes under processing, and can take from 7 to 15 days in total.